Datei:Josse Block-Cutting Machine – Longitudinal Section of the Machine.jpg

Originaldatei (979 × 588 Pixel, Dateigröße: 137 KB, MIME-Typ: image/jpeg)

![]()

Diese Datei und die Informationen unter dem roten Trennstrich werden aus dem zentralen Medienarchiv Wikimedia Commons eingebunden.

Beschreibung

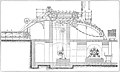

| BeschreibungJosse Block-Cutting Machine – Longitudinal Section of the Machine.jpg |

English: *Josse Block-Sawing Machine – View of the Machine, Showing the Conveyor for the Planks.

A MACHINE THAT SAWS 240,000 WOODEN PAVING BLOCKS IN A DAY. BY JACQUES BOYER. M. Josse, the director of the municipal workshops of Paris, has invented a block-cutting machine that turns out 24,000 wooden paving blocks per hour. This ingenious and complicated mechanical·device will advantageously replace the machinery and methods now in use, effecting a considerable saving in wood as well as in labor. In the early days of paving with wooden blocks in Paris, the blocks were sawed with single circular or band saws. At a later period, in order to meet the increased demand, three machines containing four or five saws each were installed in the municipal work shop. Each of these machines consisted essentially of an oscillating frame, the lower end of which carried '1 number of saws, to which the planks were fed singly by an attendant. In 1900 this equipment became insufficient, and some more expeditious method had to be devised. It must be remembered that the daily output of a municipal shop that turns out 25 million paving blocks per year cannot be uniform unless extensive facilities for storage. are provided. The trees are felled only in certain seasons, and the regularity of shipments is further impeded by the great number of purveyors and the uncertainties of the weather. Sometimes the manufacture of blocks has to be suspended for weeks, in order to take care of daily arrivals of 20 or 30 carloads of planks. The demand for blocks and the supply of old blocks are equally irregular, for paving is done only in the summer sea son. These old blocks are scraped and trimmed for further use in winter. furthermore, the demand for blocks varies from year to year. Mr. Josse, therefore, endeavored to devise a machine that would accommodate itself to all these irregularities, as well as to the sudden emergencies that are inevitable in a business of this character. The result of his studies is a huge machine 100 feet long, which divides each plank into 16 blocks by means of 17 circular saws. The planks are brought to the machine on platform cars, one of which is shown at the right of the diagram. The length of each plank is a little more than sixteen times the height of a block, as it is laid in the pavement with its fibers vertical. The width and thickness of the planks correspond to the horizontal dimensions of the blocks, when laid. Two workmen lift the planks, one by one, from the car, and lay them on a conveyor formed of two endless chains E, connected by transverse cleats. The chains run on sprockets 0 placed at the ends of an inclined frame A, and on rollers D, distributed along the upper and somewhat convex surface of the frame. Two sheet iron guides keep the planks in register and assure their proper delivery to the horizontal table, to which they are elevated by the inclined conveyor. The planks are pushed along this table by combs K, of 16 teeth, attached to two endless chains which run on sprockets. The axes J J’ of these wheels are mounted near the ends of a horizontal frame G, which terminates in two shafts, one of. which is free to turn in bearings on two posts H, while the other is supported by chains I. In front or each tooth of the combs Is a spring L. The function of these springs is to keep the planks, before sawing, and the paving blocks, after sawing, pressed to the table. Near the end of the table where the combs and springs rise and abandon the blocks, the latter are held down on the table by a set of small wheels M mounted on springs. Each comb carries two little brushes which sweep all waste into holes at the sides of the table. The circular saws protrude through slits in the table. There are 17 saws, about 25 inches in diameter, mount ed on three shafts, of which two are in line with each other but not with the third, P. This arrangement was adopted in order to avoid the excessive vibration of a single shaft as long as the planks, bearing 17 saws and making 2,000 revolutions per minute. The long shaft could not be stiffened by intermediate bearings because of the small distance between the., saws. It was therefore decided to distribute the saws among three short shafts not in the same line. Each shaft is mounted on ball bearings and is driven by two belt wheels, one at each end. The bearings rest on iron beams imbedded in masonry. Directly under the, saws, in the cellar of the building, is the main driving shaft, which carries six wheels connected by belts with the wheels on the saw shafts. The driving shaft is mounted so that it can be moved up and down, to loosen and tighten the belts. This adjustment can be made from the main floor. The saw blade is made up of a number of hinged cast-iron plates, which can be turned back for examination and adjustment of the saws. The bearings have direct lubrication. The resinous ken: which the saws accumulate from pine wood is removed by fine jets of kerosene pumped from a five-gallon tank through 3 main and 34 branch tubes and occasionally thrown on both faces of all the saws, without stopping the operation of the machine, by opening the cocks of the three main tubes that supply the three sets of saws. Each of the two sets of saws which are in line contains 5 saws and cuts from the plank a waste end or trimming and 4 paving blocks. These two sets attack the plank simultaneously. The middle portion of the plank passes on between them to the third set, which comprises 7 saws and divides the remnant into 8 equal blocks. The Hi blocks which are thus cut almost simultaneously from the plank continue to advance along the table, pushed by the teeth of the conveyor and held down by the springs L until they come under the, spring wheels M, where they remain until they are pushed onward by the following set of blocks. Thenceforward the blocks advance by steps, as they are pushed onward by new arrivals. When they reach the end of the table they slide down two inclined planes" divided into 16 compartments by vertical partitions, to the three belts of a horizontal conveyor, from which they are picked up and thrown into cars by a crew of 8 workmen. The cars, when filled, are hauled over the Decauville railway tracks to the creosoting 'establishment, whence the creosoted blocks go to the storage yards. The power which operates the saws is furnished by an electric motor U of 110 horse-power, which is installed in the basement and connected by two belts with the main shaft P'. This motor is controlled by a liquid rheostat W, with an amperemeter and a safety cut-off. Connected with a switchboard on the main floor are two additional interrupters, an amperemeter, a voltmeter, and the controlling apparatus of a 4 horse-power motor U, which supplies power to the conveyors. Finally, there is a traveling crane and windlass for the removal of the saws for resetting. The Josse machine can saw 25 planks per minute. As each plank furnishes 16 blocks, the theoretical output of the machine in a day of 10 hours is 25 x 16 x 60 x 10 = 240,000 blocks. In practice it is necessary to make some allowance for unavoidable stoppages, etc., but a small mountain of paving blocks can be turned out in a day with the aid of 20 men or less. |

| Datum | |

| Quelle | Jaques Boyer: Josse Block-Cutting Machine – A machine that saws 240,000 wooden paving blocks in a day. Scientific American, 18 April 1908, p. 273-274 (www.jstor.org/stable/10.2307/26007237 and ur.booksc.me/book/66292912/ae91c7). |

| Urheber | Jaques Boyer, Scientific American, 18 April 1908, p. 273-274. |

Lizenz

| Public domainPublic domainfalsefalse |

|

Dieses Werk ist gemeinfrei, weil seine urheberrechtliche Schutzfrist abgelaufen ist. Dieses Werk ist gemeinfrei in den Vereinigten Staaten, weil es vor dem 1. Januar 1929 veröffentlicht (oder beim U.S. Copyright Office registriert) wurde. | |

| Es wurde festgestellt, dass diese Datei frei von bekannten Beschränkungen durch das Urheberrecht ist, alle verbundenen und verwandten Rechte eingeschlossen. | |

https://creativecommons.org/publicdomain/mark/1.0/PDMCreative Commons Public Domain Mark 1.0falsefalse

Kurzbeschreibungen

In dieser Datei abgebildete Objekte

Motiv

18. April 1908Gregorianisch

image/jpeg

Dateiversionen

Klicke auf einen Zeitpunkt, um diese Version zu laden.

| Version vom | Vorschaubild | Maße | Benutzer | Kommentar | |

|---|---|---|---|---|---|

| aktuell | 00:35, 14. Jan. 2022 |  | 979 × 588 (137 KB) | NearEMPTiness | Uploaded a work by Jaques Boyer, Scientific American, 18 April 1908, p. 273-274. from Jaques Boyer: Josse Block-Cutting Machine – A machine that saws 240,000 wooden paving blocks in a day. Scientific American, 18 April 1908, p. 273-274 ([https://www.jstor.org/stable/10.2307/26007237 www.jstor.org/stable/10.2307/26007237] and [https://ur.booksc.me/book/66292912/ae91c7 ur.booksc.me/book/66292912/ae91c7]). with UploadWizard |

Dateiverwendung

Die folgende Seite verwendet diese Datei:

Globale Dateiverwendung

Die nachfolgenden anderen Wikis verwenden diese Datei:

- Verwendung auf fr.wikipedia.org

Metadaten

Diese Datei enthält weitere Informationen (beispielsweise Exif-Metadaten), die in der Regel von der Digitalkamera oder dem verwendeten Scanner stammen. Durch nachträgliche Bearbeitung der Originaldatei können einige Details verändert worden sein.

| JPEG-Dateikommentar | Cropped using GIMP 2.10 |

|---|